ANSI Gasket Sizes

Introduction: When it comes to sealing joints in piping systems, ANSI gaskets play a crucial role. These gaskets are designed to prevent leaks and ensure the integrity of connections in a wide range of industrial applications. However, navigating through the world of ANSI gaskets can be daunting, especially when it comes to understanding the different sizes available and choosing the right one for your specific needs. In this guide, we'll delve into the intricacies of ANSI gasket sizes to provide you with a comprehensive understanding.

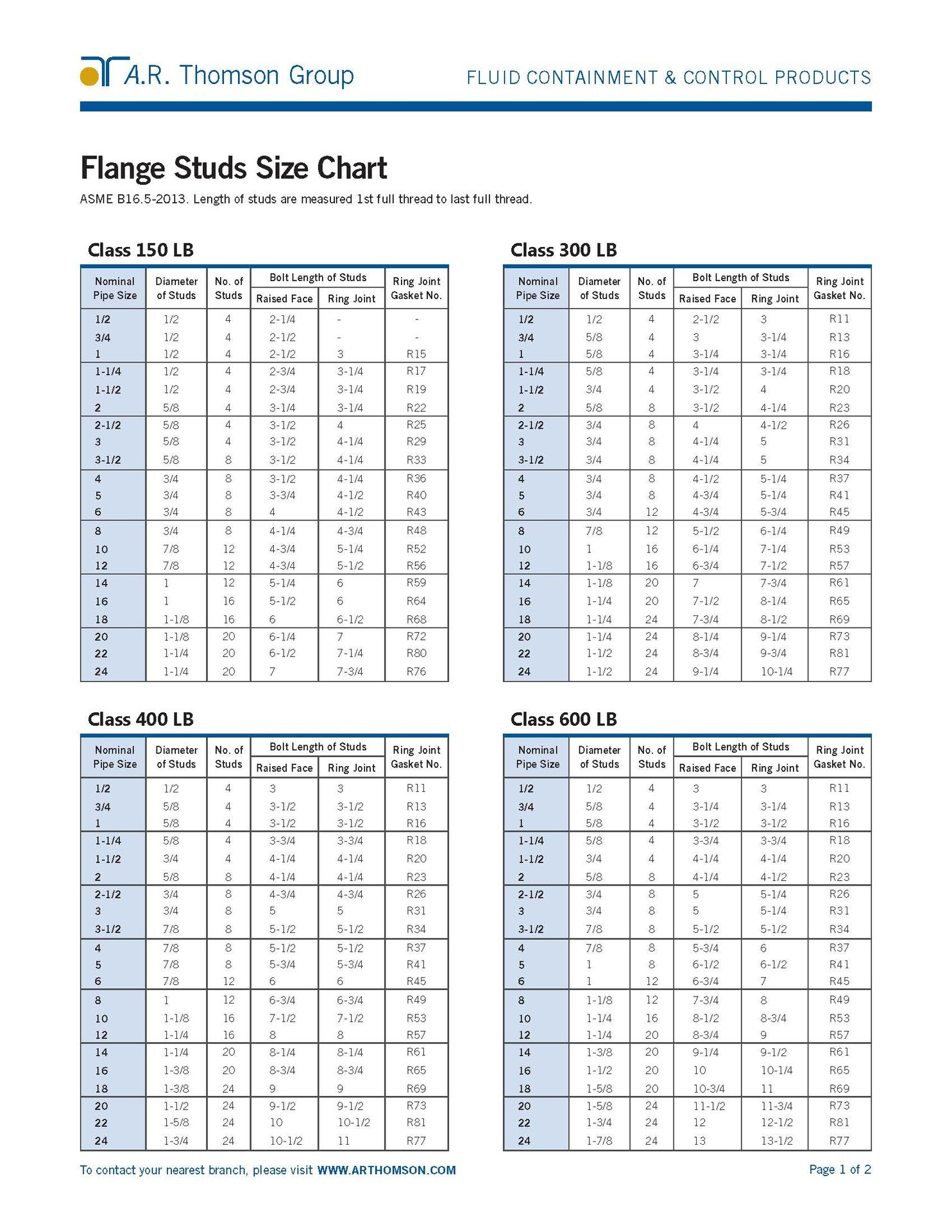

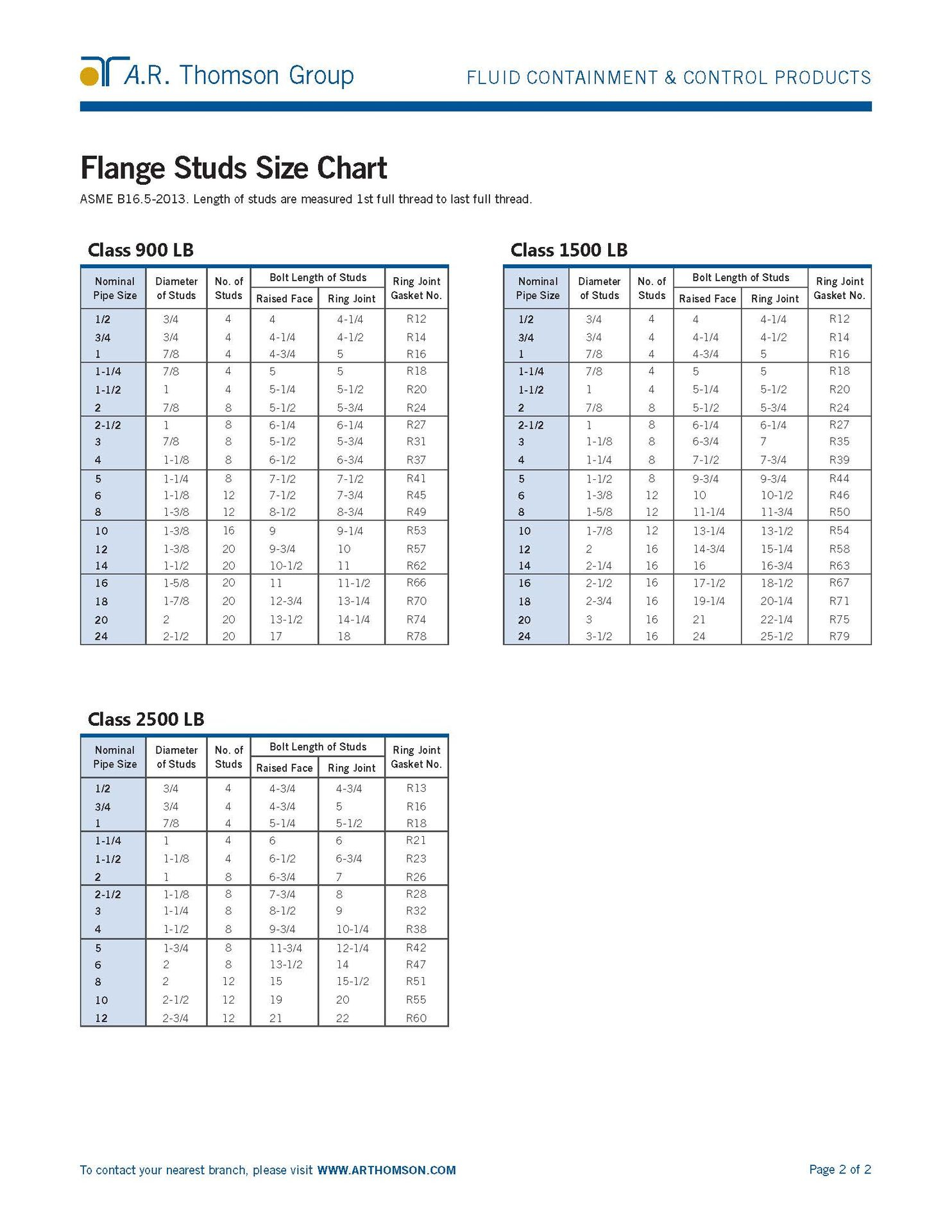

Understanding ANSI Gasket Sizes: ANSI (American National Standards Institute) has established standard sizes for gaskets to ensure compatibility and interchangeability across various industries. These standard sizes are categorized based on the dimensions of the flange they are designed to seal. The most common ANSI gasket sizes are identified by their nominal pipe size (NPS) and pressure rating.

Nominal Pipe Size (NPS): The NPS refers to the approximate inside diameter of a pipe, not its exact dimensions. ANSI gasket sizes are typically associated with specific NPS values, ranging from 1/2 inch to 48 inches or larger. It's essential to match the NPS of the gasket with the corresponding pipe size to achieve a proper seal.

Pressure Rating: In addition to NPS, ANSI gaskets are also categorized based on their pressure ratings, which indicate the maximum pressure they can withstand without leaking. Common pressure ratings include 150, 300, 600, 900, 1500, and 2500 pounds per square inch (psi). Choosing the right pressure rating is critical to ensure the gasket can withstand the operating conditions of the application.

Types of ANSI Gaskets: ANSI gaskets come in various materials and configurations to accommodate different sealing requirements. Some common types include:

-

Compressed Non-Asbestos Gaskets: Made from a blend of fibers and fillers bonded with synthetic rubber, these gaskets offer excellent sealing performance and chemical resistance.

-

PTFE (Polytetrafluoroethylene) Gaskets: Known for their exceptional chemical resistance and low friction properties, PTFE gaskets are ideal for sealing applications involving corrosive fluids and high temperatures.

-

Spiral Wound Gaskets: Constructed by winding metal strip and filler material in a spiral pattern, these gaskets provide resilience and strength, making them suitable for high-pressure and high-temperature applications.

-

Ring Joint Gaskets: Designed for use with flanges featuring a grooved ring face, ring joint gaskets are typically used in high-pressure pipelines in the oil and gas industry.

Choosing the Right ANSI Gasket Size: Selecting the appropriate ANSI gasket size involves considering several factors, including the pipe dimensions, pressure rating, temperature, fluid compatibility, and operating conditions. It's crucial to consult with gasket manufacturers or suppliers to ensure you choose the right gasket for your specific application.

Conclusion: ANSI gaskets are integral components in piping systems, providing essential sealing to prevent leaks and maintain the integrity of connections. Understanding the different ANSI gasket sizes, including NPS and pressure ratings, is crucial for selecting the right gasket for your application. By considering factors such as pipe dimensions, pressure, temperature, and fluid compatibility, you can ensure optimal performance and reliability in your piping systems. For expert guidance on selecting ANSI gaskets, consult with reputable manufacturers or suppliers to meet your sealing needs effectively.